Aiglets

This page is expanding and will have a lot of information added soon. Each aiglet in my possession, extant and modern, will be listed here with images of each and discussion.

This is an ongoing project to help organize and share what I am learning. If you have any suggestions or comments, please email me at the link in the footer of the page.

As this page is becoming very long, I have added "Read More" buttons. These will allow you to peruse the headings, decide what you want to read, and only have that expanded for your use.

Links to pages

- Here you will find additional information about all of the the Extant Aiglets in my possession.

- How to make the tools to make aiglets.

- Translated from Middle French, this page has part of a document regarding aiglets. what I am doing is more paraphrasing the Middle French then translating it.

- British Museum Research. On November 1st and 2nd, 2022 I had the opportunity to spend several hours in the "Department of Britain, Europe and Prehistory Study Room". I took several pictures and make a lot of notes of the items I studied. I purposely chose items to examine that were listed as possible and/or were uncertain of their classification as lace-tags. About half of the items I looked at I determined were NOT lace-tags.

This page will have those results. More will be added as I learn more and refine the data.

Links to documents

- Rediscovering the Process of Making Type 2 & Type 3 Aiglets While it is generally understood how type 1 aiglets were manufactured, the manufacturing process for type 2 and type 3 aiglets is not well understood.

In this 15-minute slide show, I will attempt to demonstrate some conjectured processes that may be used to manufacture type 2 and type 3 aiglets. I will also attempt to provide documentation that supports my hypothesises.

I am taking a little-studied and obscure subject and making it into an informative topic that will be educational and interesting. Presented conversationally, this presentation will be of interest to the general public as well as those who study the history of how items are made.

- Clarifying and extending the typology of aiglets, through a practical application of craft and experimental archeology. This presentation was first presented at 'The Medieval Dress and Textile Society (MEDATS), Learning Through Reconstruction Study Day' on the 29th of July, 2022.

- I am including an Excel sheet that I downloaded from the British Museum website with highlights of the items I looked at or made reference to in November of 2022.

- My 2017 monograph: Aiglets: Medieval, Post Medieval, and Modern. June 2017 (pdf) (26mb. This is a large file) This is the basis for my upcoming book.

- Insights into Understanding Aiglet Types and Manufacturing Techniques. With a focus on aiglets from the post medieval era. Powerpoint slides (2017) (pdf)

- Insights into Understanding Aiglet Types and Manufacturing Techniques. Talking notes (2017) (pdf)

- Research I have been doing about surface finishing and Polishing Copper For Aiglets

- Jerry's Basic Jewelry Bench-work 4: Making Aiglets: If you are a historical reenactor, making aiglets can be hard to do if you have never done it. This video will show you how to take a flat piece of brass and form a completed aiglet. This video works on the assumption that you have already made a mandrel, pattern and have cut out some blanks.

- Jerry's Basic Jewelry Bench - work 6: Making type 3 aiglets" is about making type 3 aiglets.

- Jerry's Basic Jewelry Bench-Work 8: Finishing the ends of aiglets is a short video explaining how to finish off the ends of aiglets.

- If you made or purchased aiglets, you need this handout for attaching aiglets

- Some possible examples of extant aiglets meant to be sewn onto garments. A short review of some extant aiglets that I think show that some aiglets were sewn and not riveted. Only 18 pages, this is a moderately large file.

Presentation: Rediscovering the Process of Making Type 2 & Type 3 Aiglets

Here is the link to Youtube to view this presentation.

Rediscovering the Process of Making Type 2 & Type 3 Aiglets. (MP3, Length 15:19)

This is a 15 minute presentation covering just the basics of this research. If you have questions, please ask!

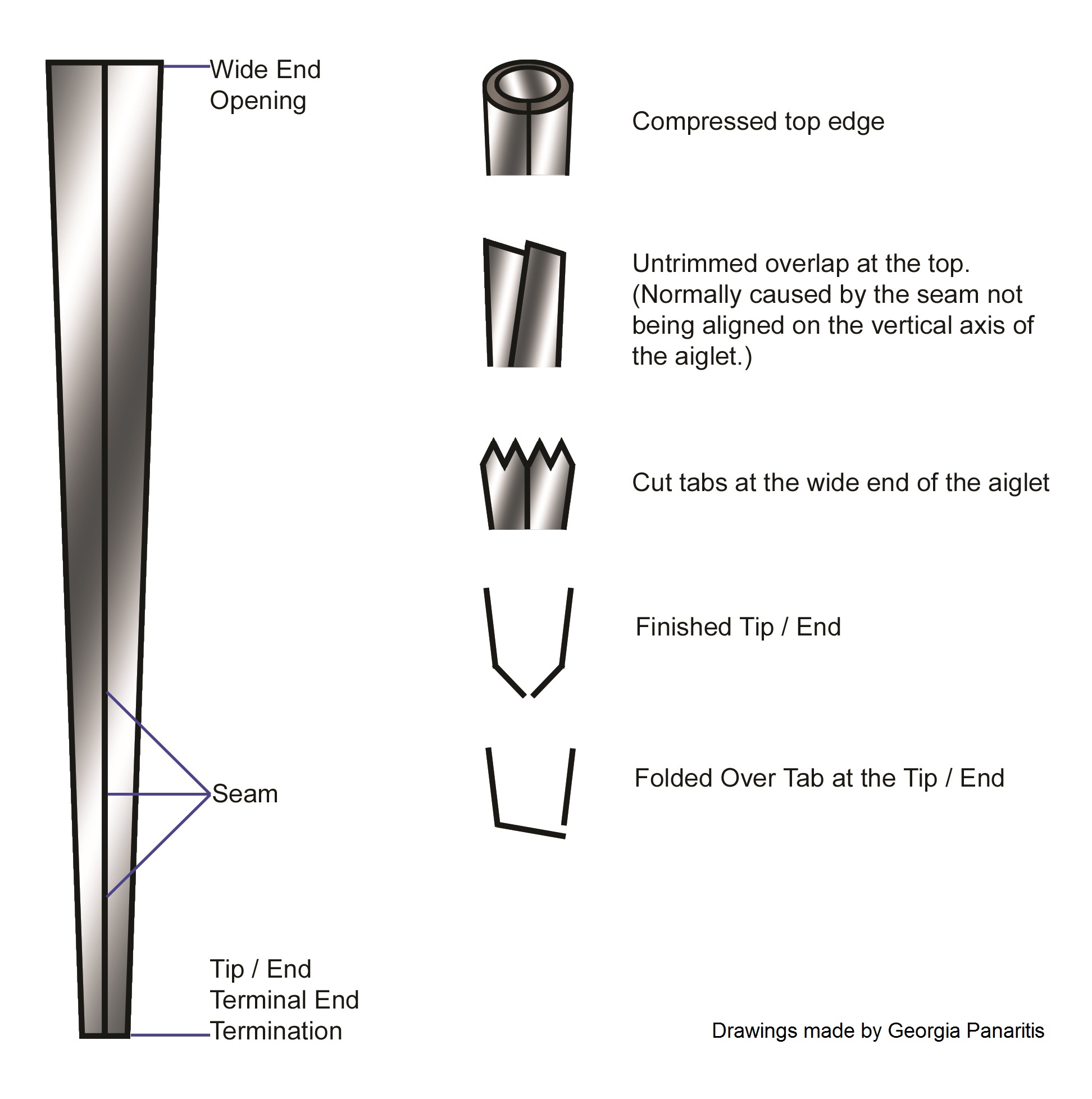

While substantial progress has been achieved in the research of clothing, textiles, and associated items over the last century, it is still the case that the body of research on the manufacturing, use, and impact on the material culture of aiglets remains rather impoverished. Despite their nearly ubiquitous presence in clothing from the 8th century on, little to nothing is known about their actual manufacture and their impact on the material culture of the societies they are found in.

Aiglets are items that are in some way used to finish the end of laces (such as shoelaces), thongs, or cords. They function to protect the cord from unraveling, easing passage through an eyelet of some sort, or adding weight to the cord.

While it is generally understood how type 1 aiglets were manufactured, the manufacturing process for type 2 and type 3 aiglets is not well understood.

In this 15-minute slide show, I will attempt to demonstrate some conjectured processes that may be used to manufacture type 2 and type 3 aiglets. I will also attempt to provide documentation that supports my hypothesises.

I am taking a little-studied and obscure subject and making it into an informative topic that will be educational and interesting. Presented conversationally, this presentation will be of interest to the general public as well as those who study the history of how items are made.

Please share this with all of your social media outlets.

Below are thumbnails of the 22 slides. These will open in a new window.

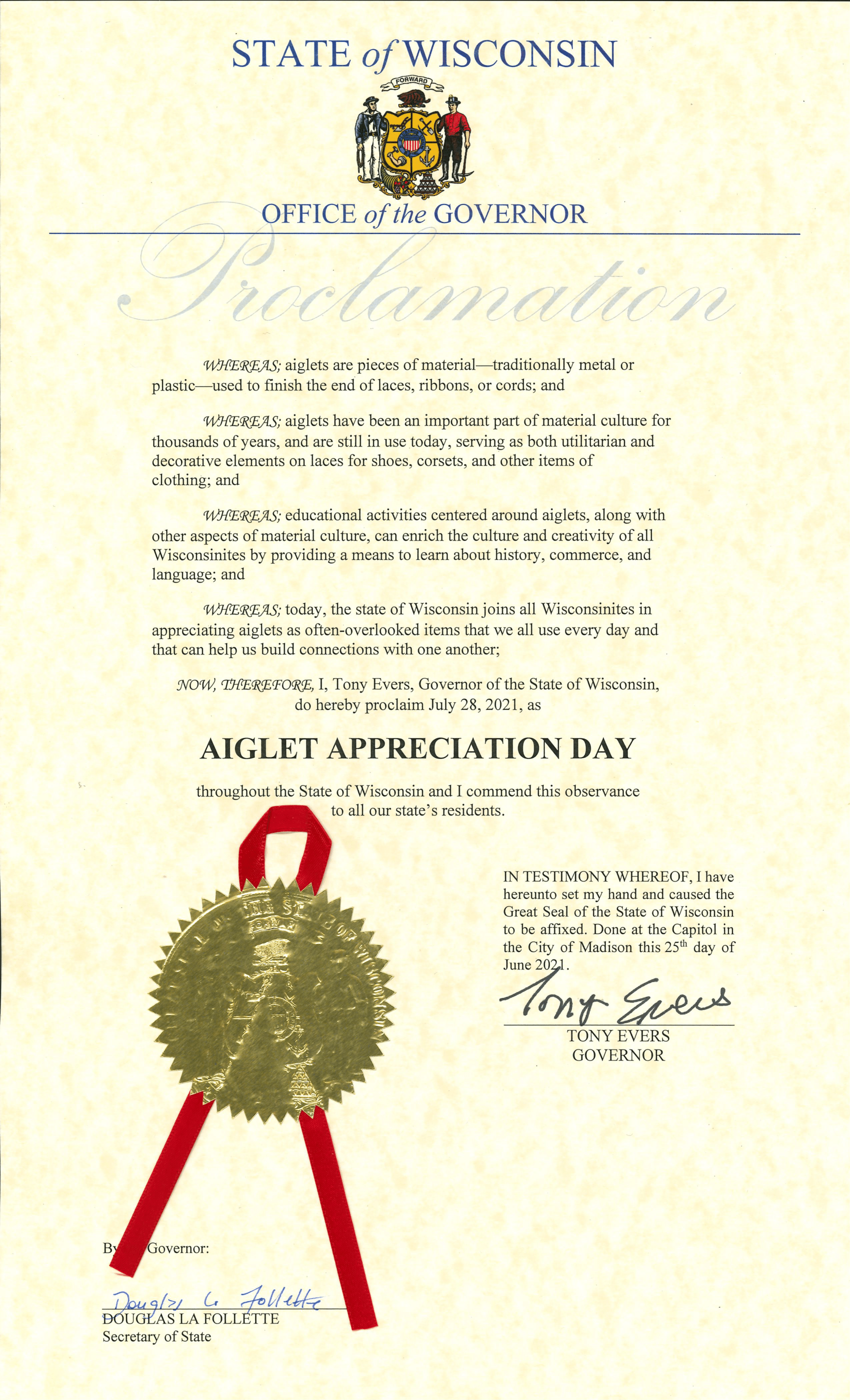

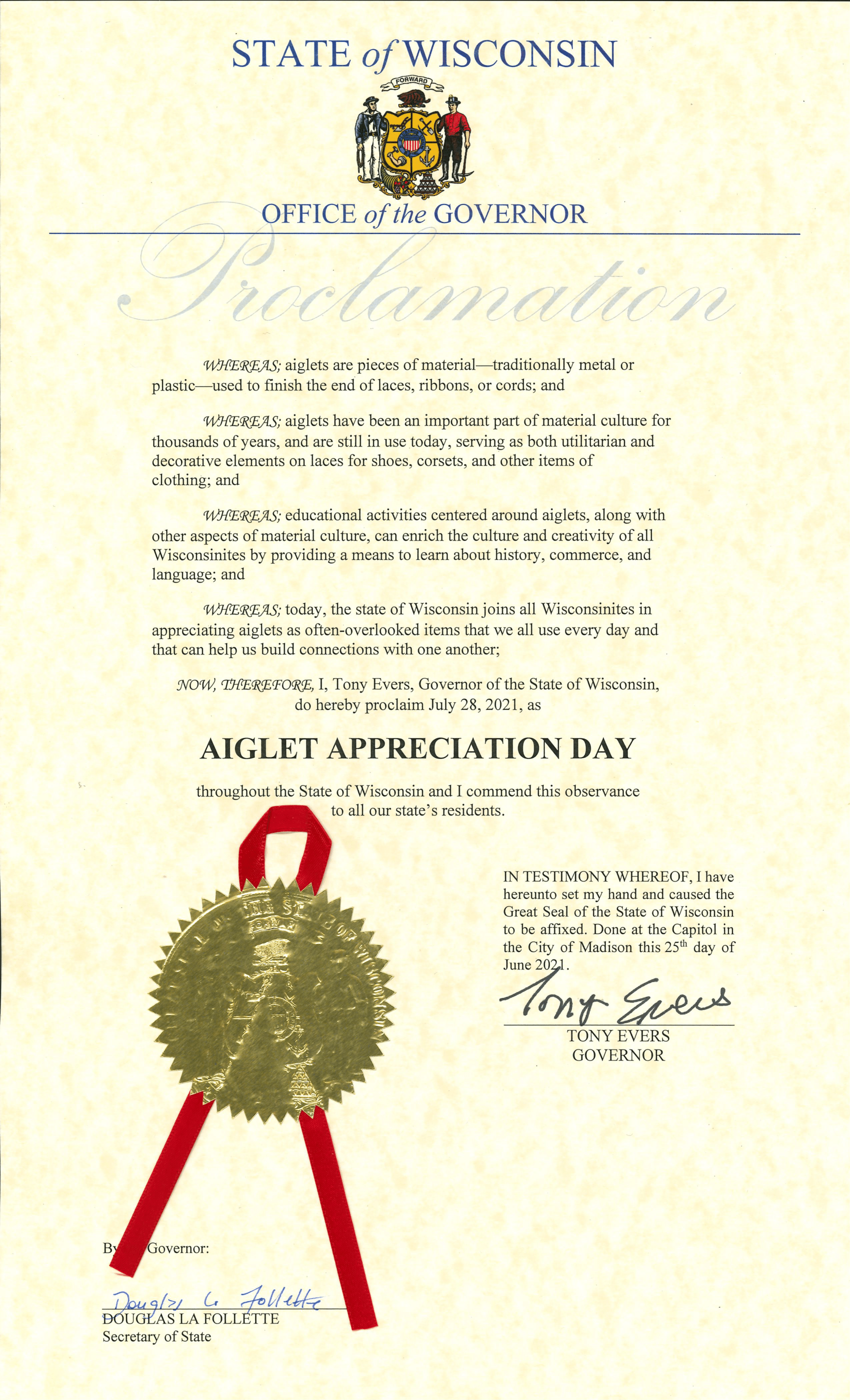

Aiglet Appreciation Day is July 28, 2021

A proclamation from Governor Evers

My name is Gerald Livings. I am an independent researcher who has for most of the last decade been studying aiglets (aglets) and how they affect material culture worldwide and locally, in the far past as well as today.

I have requested, and been granted, a proclamation from Governor Evers that makes July 28th, 2021, the official Wisconsin “AIGLET APPRECIATION DAY”.

While this proclamation is only official in the State of Wisconsin, I do think that on July 28th, EVERYONE CAN CLAIM TO BE FROM WISCONSIN!

Now I hope you already know what aiglets are. But if you do not, look at your feet. There is a good chance you have some shoelaces on and if so, you are also wearing aiglets. They are the little things on the ends of the shoelaces that is keeping them from unraveling.

Aiglets are used to finish the end of laces, thongs or cords. Aiglets still are in use today in the 21st century where they are utilitarian as well as decorative elements on laces for shoes, corsets and other clothing.

Whereas aiglets have been an important part of material culture for thousands of years, I am planning to hold educational activities centered around to learn about history, commerce, language, and material culture.

I will be posting documents and lesson plans on this page as I prepare them.

As aiglets have been around for literally thousands of years, I chose this date as I feel it will be a good time of the year to plan educational activities around. Just before school begins, and simple activities based around shoelaces, aiglets, the social & economic impact, and history of aiglets can be used to bring people together for a fun day of learning.

It has always been my belief that supporting educational activities is a critical strategy for our state, and all Nations to compete in the global economy and to develop healthy, vibrant communities where people want to live, work, learn, and play.

Help me spread the word about this very important day.

Thank you.

The 5th Annual Symposium on Medieval and Renaissance Studies

I am honored to be presenting a longer version of my paper at the 5th Annual Symposium on Medieval and Renaissance Studies, hosted by the Center for Medieval and Renaissance Studies on the campus of Saint Louis University.

Wednesday, June 21, 2017, 8:30am - 10:00am Plenary Session W12 - The British Isles in the Tudor-Stuart Period.

Chair: Thomas Finan, Saint Louis University

Room: Cook Hall, Room 240

I am the second of 3 speakers in this session.

Aiglets: Medieval, Post Medieval, and Modern,

Gerald Livings, Independent Scholar.

The video of my presentation "Insights into Understanding Aiglet Types and Manufacturing Techniques. With a focus on aiglets from the post medieval era." will be available in early July of 2017.

Congress on Medieval Studies

Hosted by Western Michigan University's Medieval Institute, the 51st International Congress on Medieval Studies is an annual gathering of around 3,000 scholars interested in medieval studies.

The 51st International Congress on Medieval Studies

DISTAFF session 1, The 51st International Congress on Medieval Studies, May 12-15, 2016.

Paper 4: Techniques for Manufacturing Aiglets in Sixteenth-Century England: Comparisons and Conjecture

Gerald A. Livings, Independent scholar.

Session 456, Saturday 3:30 p.m. in the Schneider building room 1120.

This is my first paper I have presented so please be forgiving of any grammatical errors. I suspect it will have a few flaws but as a non-writer I am happy with it. Please see the links at the top of the page.

Please note the paper name has changed from "Techniques for Manufacturing Aiglets in Sixteenth-Century England: Comparisons and Conjecture" to "Aiglets: Medieval, Post Medieval, and Modern". The name of my presentation did not change.

The original paper "Aiglets: Medieval, Post Medieval, and Modern" presented in 2016 is now out of date. Please use the link above to download the current version of this paper dated June 2017.

A common lexicon for conversation.

One thing that is needed is a common way to talk about a subject. Without words that have a common meaning, there can be little or no exchange of information. For example. The word "aglet". Does it mean a computer program? A type of airplane? Or the thing on the end of a shoelace?

Yes.

It means all three. So we must decide which type of "aglet" we are discussing and then find a common vocabulary so we may discuss them. That is why I chose to use the spelling that uses the letter "I" as it is less common and helps differentiates between the different types of aglets.

In that mater, I am adding this small section to show the different definitions and words that may be used, and any information from other fields of interest that will have bearing on the discussion of aiglets.

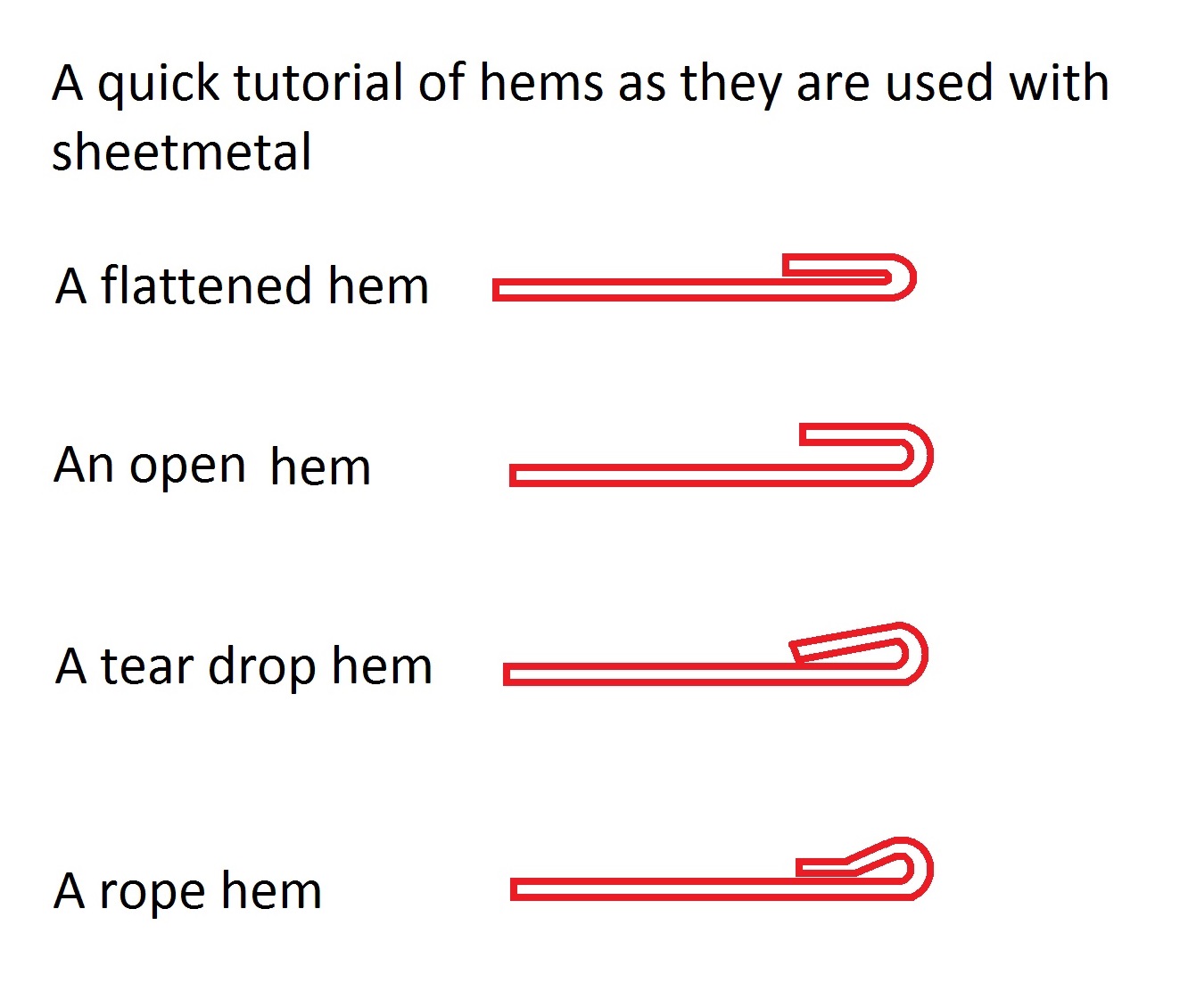

Discussion about metal seams as it relates to aiglets.

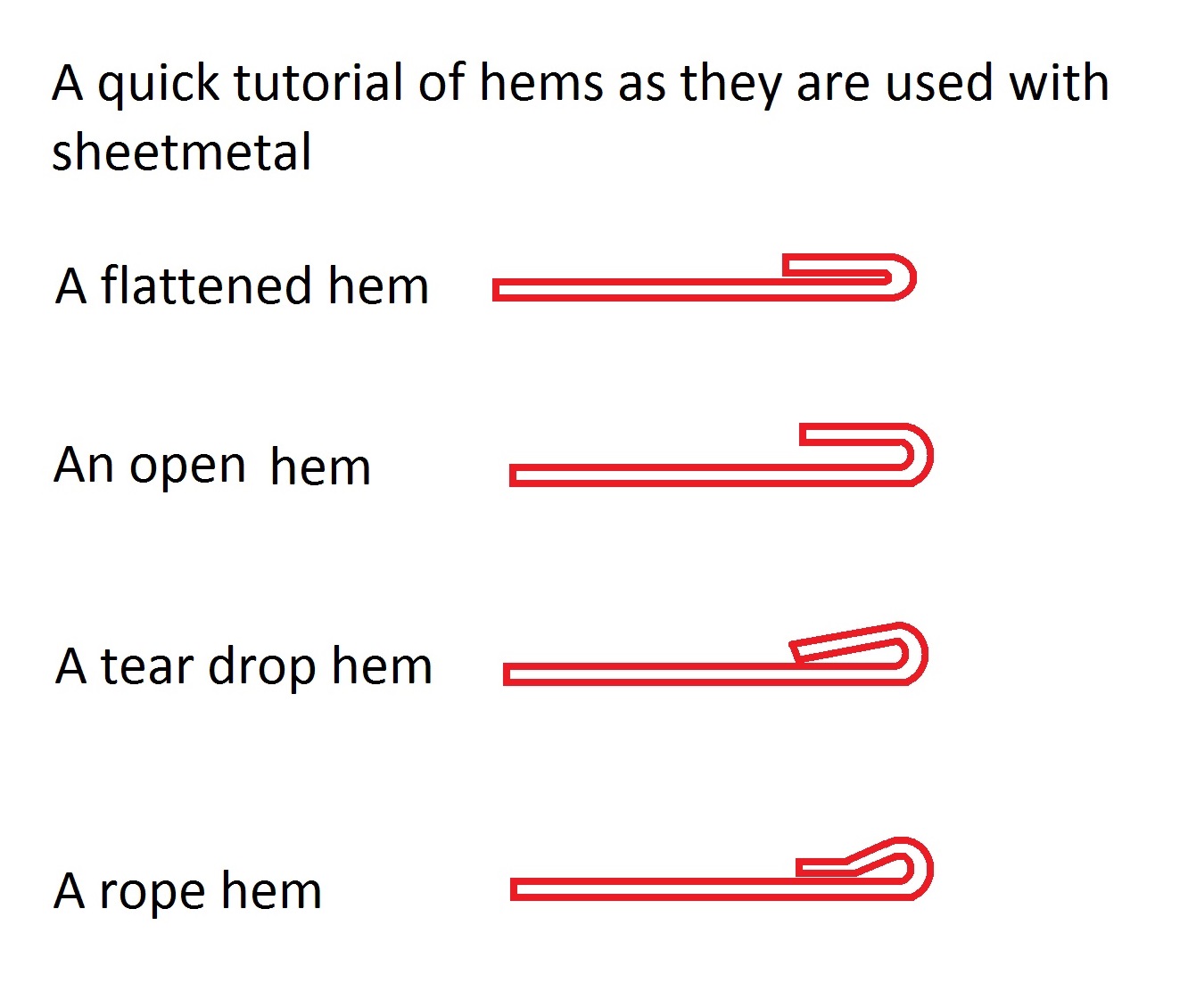

How do you talk about a piece of metal when the edge is folded over? There is not a uniform lexicon where metal seams are discussed in archaeological terms, so the system of speaking about metal meas from the HVAC industry seems to be the most relevant.

A "seam" is defined by a line along which two or more pieces of metal meet along a common plane.

When a piece of metal is folded over, that is called a "hem".

Hems come in several varieties and the chart below shows a visual description of each.

Hems

Hem / aiglet Types

How does this relate to aiglets?

By letting us discuss and convey with accuracy a verbal description of what we see.

We can most accurately describe the types of aiglets by also making sure we use precise terms in the description. While most often this precision of terminology is not needed, it is recorded here for when that precision is needed.

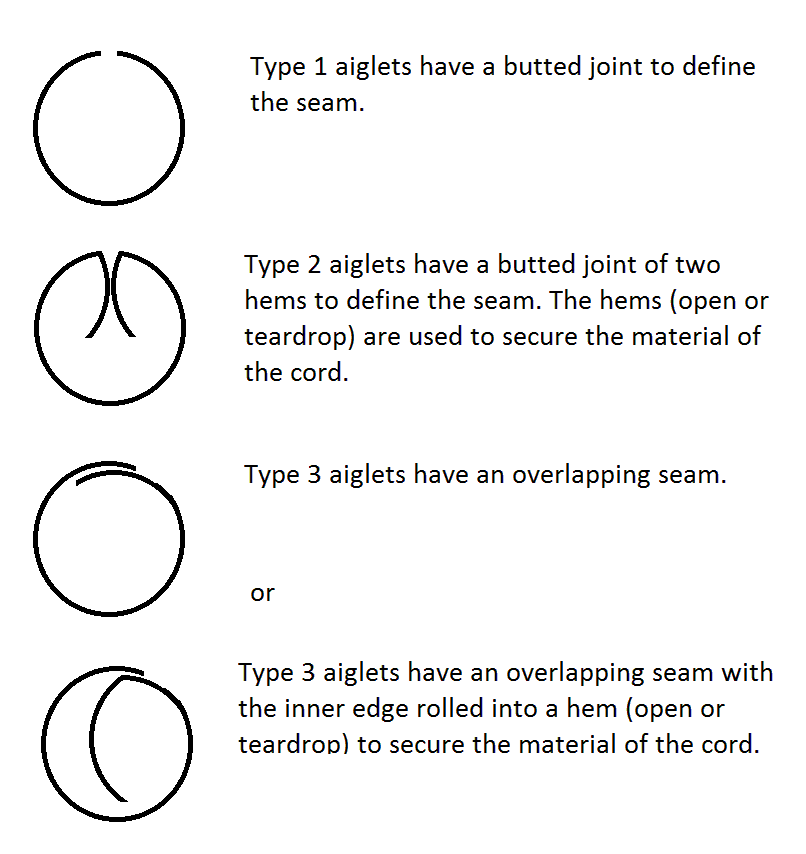

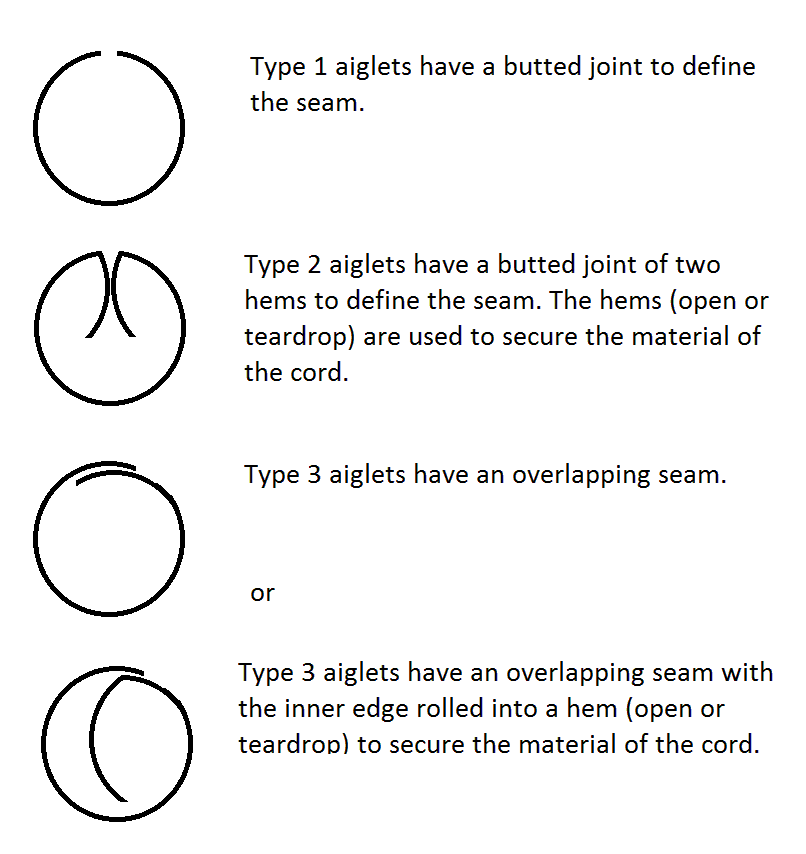

Aiglet Types

Under the current system of defining aiglet types, there is too much overlap in the descriptions of aiglet types.

Therefore I propose the following definitions for types of aiglets.

Type 1 aiglets have a seam defined by the edge of the metal butting against each other along the majority of the seam. The edges may overlap for a short distance at the base and/or the top of the aiglet.

Type 2 aiglets have both sides of the seam folding inward to grip the cord or lace along the majority (75% or more) of the seam.

Type 3 aiglets have an overlapping seam where one side of the aiglet overlaps the other side along the majority (75% or more) of the seam. One side of the seam may, or may not, be bent in to hold the cord or lace.

Type 4 aiglets are cast, forged, or are made from solid metallic materials other than sheet.

Type 5 aiglets are manufactured from non-metallic materials. (bone, horn, stone, pottery, amber, etc.)

Type 6 aiglets are purely decorative and are not functional. They may be similar to any other style of aiglet in manufacturing.

A discussion of "Provenance" and "Provenience" .

I will start with the definitions of these words from the The Oxford English Dictionary.

- Provenance

- The place of origin or earliest known history of something.[5]

- Provenience

- Another term for provenance.

When discussing art history, "provenience" and "provenance" are two words that are generally synonymous with each other according to scholars working in the field. for art, scholars and academics are more interested in verifying the authenticity of an artifact or a piece of art. In the art world, this is important to eliminate the possibility that the object was forged. "the chain of ownership" is very important for art items.

However, to archaeologists, these two words are not synonyms, in fact, there is a very distinct meaning to each in scholarly writings and discussions.

Archaeologists generally do not care who owned an object. The context of an object within the material culture of its users is more important. For archaeologists and scholars to maintain that an object has meaning and intrinsic value, they needs to know how it was used, the archaeological site it was found at, and where it was deposited within that site. The context of the artifact is important information about an object, context which is often lost when an artifact is bought by a collector and passed from hand to hand and seller to buyer.

"Provenance" means "the history of ownership of a valued object" and it is the oldest (or parent) of the two words.

"Provenance" is derived from the French word 'provenir', meaning "to come forth", and it has been in use in English since the 1780s. Provenience is the younger (or child) of the two words. It may be used in some discussions as a synonym for "provenance" and it has been in use in English since the 1880s.

Artifact Context is important. So we end up with two words. One to show the chain of ownership for art historians, and one to define the context of an object for archaeologists.

I am not a professional archaeologist so below is how I interpret these two words. As much as possible, I will use make a point to discuss both in my writings as appropriate.

- Provenance

- The history of the ownership of an artifact from either it's creation, from when the artifact was first excavated, or both. (This is akin to an artifact's resume.)

- Provenience

- The exact location and time where an artifact was first excavated archaeologically.(This is an artifact's birthplace.)

Due to this I will always record and share the provenance of the items that I am using to such a degree that I am able. Many times, the items will not have a documented provenance that satisfies professional archaeologists and scholars. As I am located in the United states, it is hard to acquire aiglets for study. So I will do as much as I am able.

For the provenience of the items that I study, I will try to narrow down the information as much as I am able. Also, I will record as much information that I learn about where the items I study were found.

Concerning roman aiglets.

I will start by saying that all of the references to roman aiglets end up either having zero documentation, or circular documentation.

I am not saying that the Romans did not use aiglets, but I can not say at this time that I have found any trustworthy documentation showing that the Romans ever used aiglets.

Further research is needed on this subject.

Images and pictures of these two artifacts have been passed around the internet as proof that the Romans used aiglets. The sites using this documentation are guilty of circular reporting, also called false confirmation. It is sloppy research and spreads disinformation.

After acquiring these two items, I can say that while in construction they are made in a similar way to type 1 aiglets, they are better characterized as either strap ends or something not unlike US Army Dress Aiguillettes [4] . As these are round, I hesitate to call them chapes for use on scabbards. One possibility is that they are military finials. They could also be butt spikes of some sort though this is doubtful as they are not sturdy enough in my opinion to work well in this capacity.

Roman chapes

Dress Aiguillette Shoulder Cord